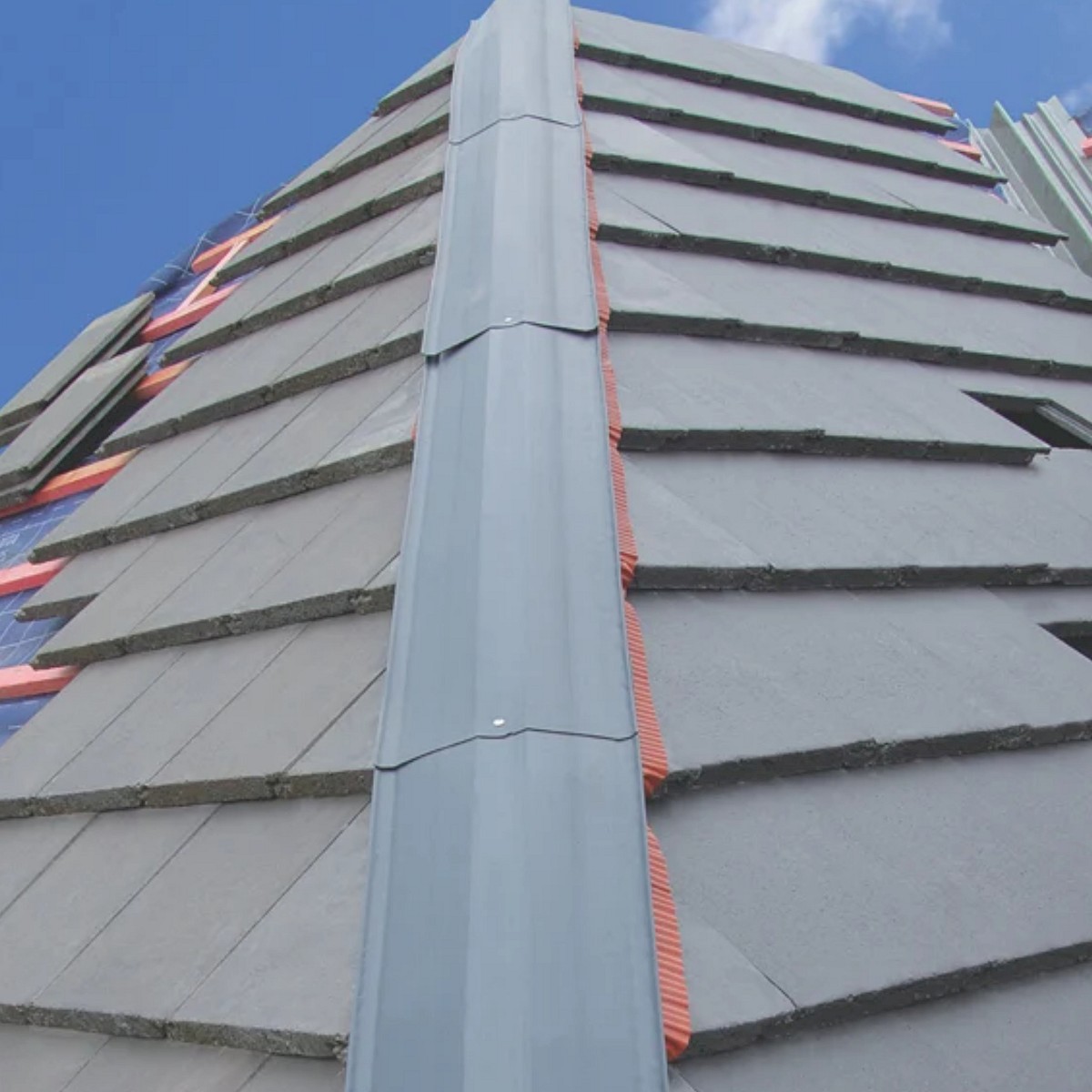

Hip Support Tray

Our Hip Trays offer a quick and reliable solution for creating a strong, level base along the hip line of pitched roofs - ready for a professional dry-fix finish. Lightweight, easy to install, and UK-manufactured, these support trays are ideal for both new builds and refurbishments where a clean, uniform roof finish is essential.

Product Overview & Specifications

Dry Hip Trays (also known as Hip Support Trays) are designed to provide a consistent, level platform along the hip line of a roof, eliminating the need for traditional mortar bedding. This not only speeds up installation but also enhances long-term weather resistance, making them a reliable choice for today’s modern roofing systems.

Whether you’re working on a new build or retrofitting an existing roof, these trays help align and support hip tiles or caps while safeguarding vulnerable roof junctions from wind and rain ingress.

Product Specifications

Length: 1200mm

Pack size: 6 trays

Material: Durable, weather-resistant PVC

Key Benefits

Mortar-free installation for faster, cleaner roofing

Quick and easy to install – no specialist tools required

Suitable for all weather conditions

Lightweight and easy to handle

Ideal for new builds and refurbishments

Manufactured in the UK

Creates a consistent finish along the hip line

Reduces installation time and labour costs

Contact Us

Want to talk to us about our products? Get in touch

Or why not give us a call on +44 (0) 1226 444350

Installation Guidelines

- Prepare the roof: Ensure the roof is lathed, and hip and ridge battens are fixed into the hip rafters using screws.

- Roll out the ridge underlay: Fix the dry ridge roll-out system in place using corrosion-resistant nails.

- Install the hip trays:

- Begin at the eaves and work upward.

- Each tray should overlap the one below by a minimum of 150mm to ensure full coverage and water runoff.

- Secure each tray into the hip batten using stainless-steel nails.

- Trays may be cut to length if needed using a suitable cutting tool. We recommend using appropriate PPE and a fine-tooth saw or plastic cutting tool rather than a utility knife for safety.

Always consult the roof tile manufacturer’s guidance to ensure full system compatibility.